ELVEZ d.o.o. joins DiMAT to advance the future of Materials Manufacturing

As part of the DiMAT Early Adopters Programme, participating companies were profiled through F6S Innovation, which gathered key information including company background, field of work, digitalisation needs, and the specific DiMAT solutions tested.

Over the course of March and April 2025, companies received personalised guidance from DiMAT experts to identify the most relevant tools for their specific business and production needs. Through interactive demonstrations, dedicated one-on-one sessions, and structured feedback exchanges, early adopters had the opportunity to deepen their understanding of advanced digital technologies and directly influence their development to better align with real industry challenges.

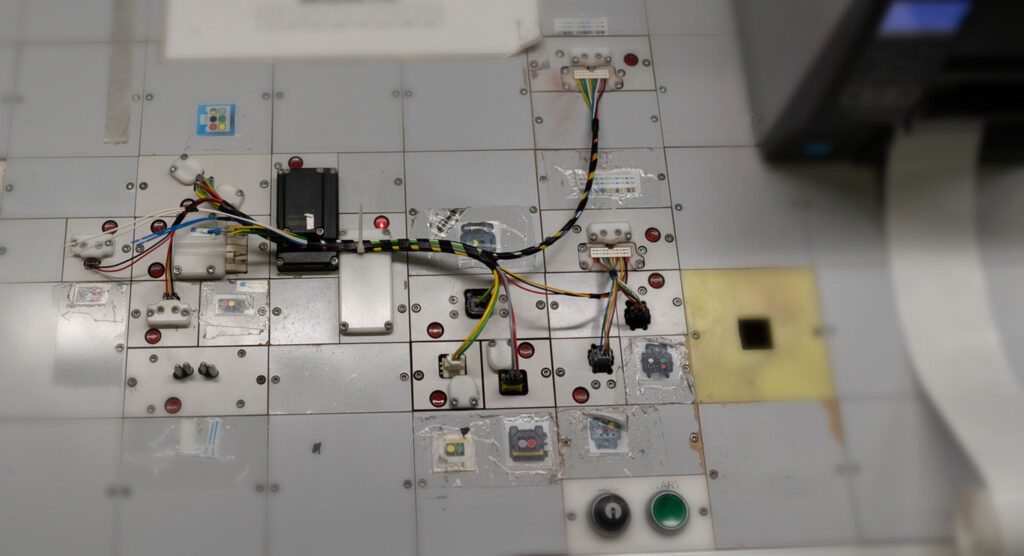

Among 3 companies selected for the programme is ELVEZ d.o.o., a Slovenian-based manufacturing specialist renowned for its expertise in plastic injection molding, metallization, and wire harness production. ELVEZ joined the DiMAT initiative to push the boundaries of sustainable innovation and to strategically integrate advanced materials science into its already robust operations.

Why ELVEZ Joined the DiMAT programme?

“Our goal was to explore how digital tools could enhance our understanding of recycled and technical materials, especially in plastic injection molding,” explains Žiga Gosar, Director of R&D and Technology at ELVEZ. With over a decade at the company, he has led major advancements in high vacuum metallization and automation for the automotive lighting industry.

Through its involvement with DiMAT, ELVEZ aimed to strengthen its capabilities in simulation and sustainability: two critical pillars for future-proofing production in a rapidly evolving market. “The opportunity to evaluate tools for life cycle analysis, mechanical simulation, and predictive modeling was exactly what we needed,” Žiga notes.

Digital Tools tested by ELVEZ

During the two-month collaboration, ELVEZ tested several of DiMAT’s flagship digital solutions:

- DiKAF –Knowledge Graph for contextualized materials data and DiMEC-LCA – Environmental and Cost Life Cycle Assessment, for efficient material and process data management, knowledge representation and life-cycle analysis.

- DiMM and DiMMS – Mechanical Properties Simulator for AI-powered Materials Modeler for advanced modeling, prediction, and material design.

- DiMPS – Materials Processing Simulator to to enhance simulation, prediction and optimisation.

“The graphical interfaces, especially in DiMEC-LCA, were very intuitive and made complex data accessible, even to team members without deep technical expertise,” says Žiga.

He highlights DiMM’s predictive modeling features as particularly valuable, reducing the reliance on physical prototypes and accelerating development cycles.

Outcomes and strategic impact

For ELVEZ, the key takeaway from the DiMAT experience was clear: digital transformation is not only achievable for SMEs, it’s essential: “We’ve already started initiatives to better track and simulate the behavior of scrap plastics internally. We’re also integrating LCA thinking earlier into product design, not just after production”.

This shift marks a strategic evolution for ELVEZ, aligning product development more closely with both environmental goals and customer expectations.

Future outlook: Building digital competence in manufacturing

Looking ahead, ELVEZ sees simulation and data-driven decision-making as important to its growth. “Digital tools will become core to staying competitive, especially in areas like sustainability reporting and circular material use,” says Gosar. The company is now investing in building internal competencies to embed simulation and predictive modeling across R&D and production workflows.

Yet, he is also realistic about the challenges SMEs face in this journey: “There’s often a perception that digital transformation is too complex or costly for smaller manufacturers. But tools like those offered through DiMAT make it accessible and tailored to our needs.”

Advice to Fellow Innovators

To SMEs exploring digital adoption, Žiga Gosar offers pragmatic advice: “Start small and focus on solving a real problem. Collaborations like DiMAT give you the chance to test powerful tools without making major commitments upfront. And importantly, involve your engineers early, they’re key to long-term success.”

Partnership for the future

ELVEZ’s participation in the DiMAT Early Adopters Programme has not only yielded practical benefits, but also opened the door for continued collaboration. As the company moves forward with its digital transformation roadmap, it remains eager to contribute to the broader dialogue on sustainable manufacturing in Europe.

“We’re very open to further exchanges and opportunities that build on the DiMAT solutions,” says Gosar. “It’s about growing smarter, together.”